Innovative Pipe Material Testing for Sewer Systems

Discover cutting-edge technologies in pipe material testing for enhanced sewer inspection accuracy and safety.

Innovative Pipe Material Testing for Sewer Systems

Introduction

In 2024, the sewer inspection industry is experiencing a technological revolution. With increasing urban infrastructure demands and smart city initiatives, pipe material testing has become more critical than ever. This article delves into the latest advancements, regulatory changes, and best practices in pipe material testing, providing valuable insights for professionals in the field.

Technological Advancements in Pipe Material Testing

Advanced CCTV Inspection

High-definition CCTV cameras equipped with pan-and-tilt capabilities and AI-powered automated defect detection represent the forefront of pipe material testing. These systems allow for precise identification of cracks, corrosion, and blockages inside pipes, offering a comprehensive view of pipe conditions.

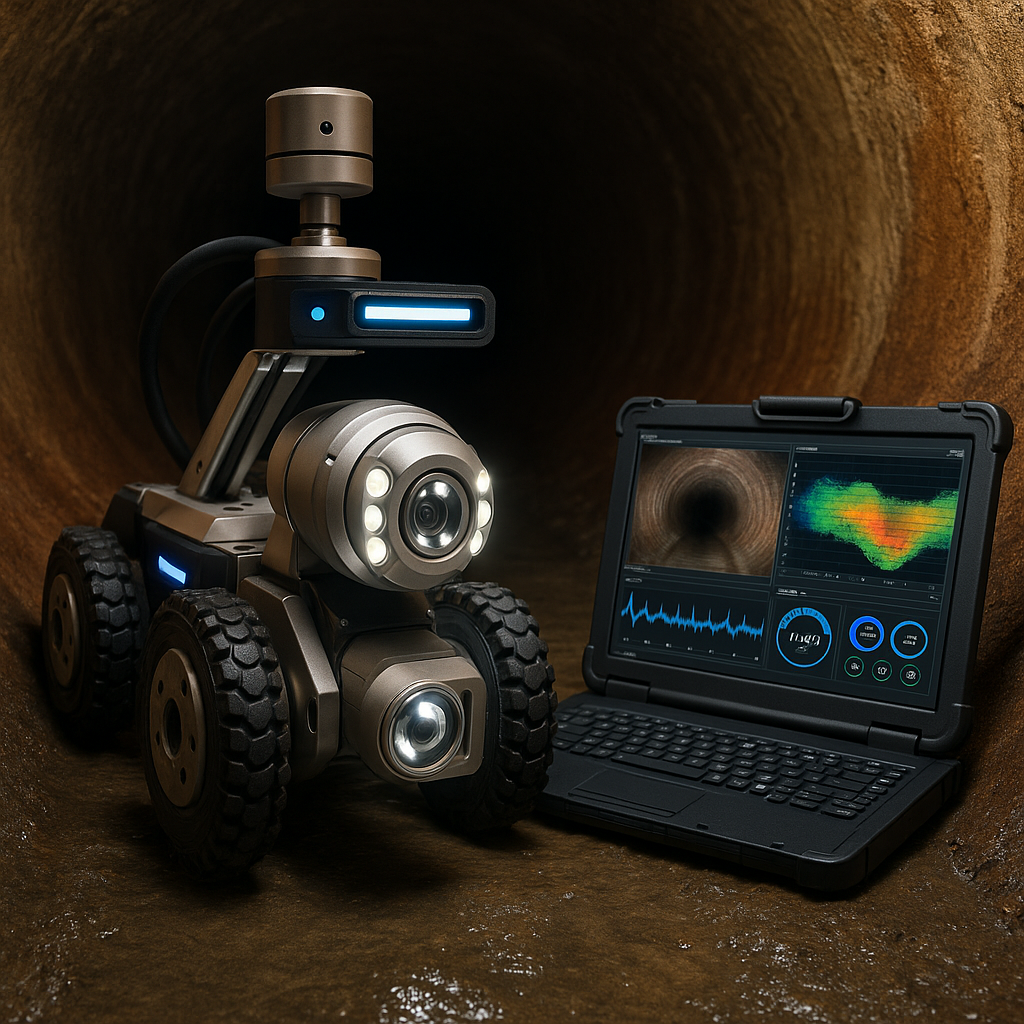

Multi-Sensor Robotic Systems

By integrating camera arrays, LiDAR, and 3D vision technologies, multi-sensor robotic systems enhance damage detection accuracy beyond traditional 2D imaging. Deep learning models process data in real-time, providing detailed insights into pipe material integrity.

Real-Time Monitoring and Data Analytics

Sensors and smart mapping tools provide instant data on pipe conditions and flow, facilitating predictive maintenance and early leak detection. These technologies help optimize maintenance schedules, reducing overall costs and enhancing system reliability.

Remote and Robotic Inspections

The use of drones, robots, and portable gas detectors minimizes the need for confined space entry, significantly enhancing worker safety. These technologies also allow for inspections in otherwise inaccessible areas, ensuring comprehensive system evaluations.

Industry Regulations and Standards

Compliance with Environmental Regulations

Adhering to EPA and local environmental regulations is crucial for sewer inspection businesses. Automated digital reporting and detailed inspection records aid in compliance, reducing the risk of violations and supporting audits.

Navigating Regulatory Complexity

While regulatory complexity can pose challenges, it drives demand for advanced inspection technologies that ensure infrastructure safety and environmental protection. Businesses must stay informed about regulatory changes to remain competitive and compliant.

Market Trends and Business Opportunities

Market Growth Projections

The sewer inspection systems market is projected to expand from USD 500 million in 2024 to USD 800 million by 2033. This growth is fueled by urban development and the integration of smart city technologies.

Opportunities in Smart City Integration

Smart city initiatives present opportunities for innovative inspection solutions that combine ICT with infrastructure management. Companies that invest in smart technologies can gain a competitive edge in the market.

Overcoming Challenges

High initial investments and technical training requirements remain barriers to widespread adoption of advanced inspection technologies. However, the long-term benefits of reduced maintenance costs and improved system reliability make these investments worthwhile.

Safety Protocols and Best Practices

Enhancing Worker Safety

Remote inspections reduce exposure to hazardous gases and confined spaces, lowering injury risks. The use of portable gas detectors and real-time video feeds further improves hazard detection before entry.

Ensuring Safety Compliance

Digital logs and automated safety tracking systems ensure adherence to safety standards, promoting continuous improvement in safety protocols.

Cost and Pricing Considerations

Cost Implications of Advanced Technologies

While advanced camera systems and robotic inspections involve higher initial costs, they offer significant long-term savings through early problem detection and predictive maintenance.

Pricing Models for Inspection Services

Inspection processes typically involve camera insertion via cleanouts or sewer traps, with costs varying based on technology used and system complexity. Businesses should consider these factors when pricing their services.

Relevance to Pipe Material Testing

Advantages of Advanced Technologies

Pipe material testing benefits from technological advancements by enabling detailed internal condition assessments and early detection of material degradation. Multi-sensor and AI-enhanced inspections provide richer data sets for evaluating pipe material integrity and lifespan predictions.

Aligning with Industry Standards

Compliance with safety and environmental regulations ensures that pipe material testing aligns with industry standards and sustainability goals. This alignment is crucial for maintaining infrastructure safety and protecting the environment.

Conclusion

The sewer inspection industry's shift towards AI-enhanced, multi-sensor robotic inspections, real-time data analytics, and remote safety-focused protocols significantly enhances the accuracy, efficiency, and safety of pipe material testing. These developments open new market opportunities, despite challenges related to cost and regulatory complexity.

By embracing these advancements, sewer inspection businesses can improve their service offerings, enhance safety, and ensure compliance with industry standards, positioning themselves for success in the evolving market.